Innovation

Texen’s commitment to innovation as a collaborative challenge

Texen is focusing on innovation to shift its entire value chain towards an agile, economic, and eco-responsible model.

In the context of ecological transition, where brands are defining the codes for a new kind of luxury in line with their economic models, Texen is assuming a major role in transforming the packaging world. Its approach vis-à-vis its customers, is based on collaboration.

Backed by the Innovation Cell’s investigation into materials and processes, Texen’s industrial model is maturing as it moves towards cutting-edge processes and technologies. These innovative alternatives are conditioned by a consistent logic focused on eco-design.

Texen is championing eco-materials coming to industrial maturity

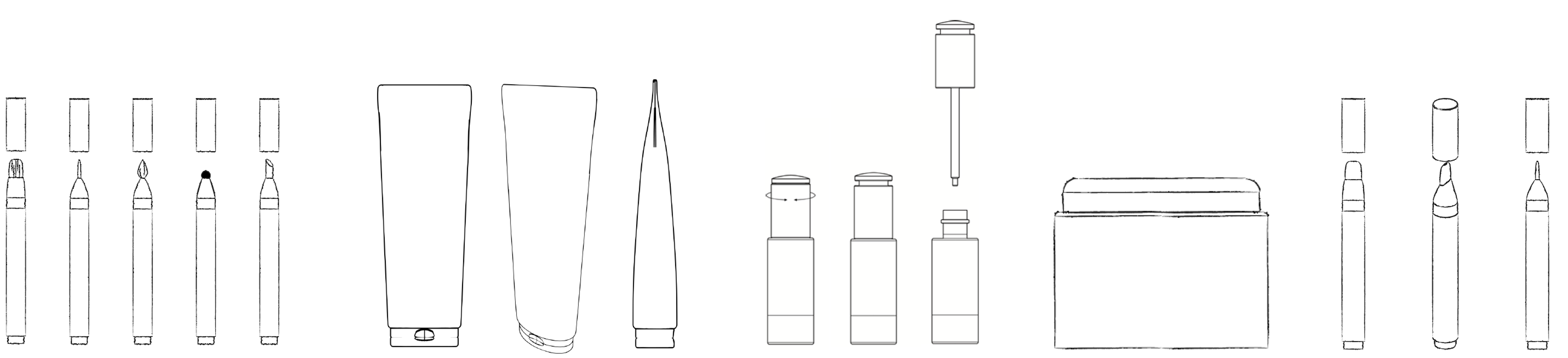

As part of its environmental commitment, Texen draws upon patented technology to transform and enhance new materials such as recycled or biosourced resins: BESST (Beauty Experience Sensation Surface by Texen). Through controlling mould temperature during the injection phase, this solution optimizes the flow of materials for complex parts, including ultra-thin depths. It guarantees surface quality and shiny, matte, or textured contrast. This technique is a structural feature of Texen’s industrial offering for brands, paving the way for innovative partnerships focused on environmentally sustainable developments.

Texen is innovating through a new agile, economical, and responsible industrial model

Texen is adopting a new industrial process capable of shortening development timeframes and cutting costs. It also helps limit volatile organic compounds (VOCs).

This patented process, called SMART® (Speed/Modularity/Agility/Reliability/Texen) draws upon the modularity and versatility of automated lines. It uses a versatile, modular platform based on the PLUG and PLAY principle that can incorporate injection, assembly, decoration, and varnishing. This is a miniaturized, 100% robotic and connected (4.0) response to 3 major challenges: agility, competitiveness, and eco-design.

The Innovation Cell

This creative and technical cell complements our industrial facilities, developing cross-cutting projects for the whole group. It also interacts with brands, providing the flexibility of an autonomous cell. It’s led by a dedicated team, fostering close links with key players in its market. The Innovation Cell is equipped with advanced machinery alongside various analysis tools and a fab lab for 3D printing.

This tool tests new concepts and decoration, designs test moulds, and produces all kinds of prototypes, samples, and pre-series. It acts as a framework for all trials necessary to approve and reference innovative materials (materials library) in strict compliance with all product safety requirements (compatibility, resistance, strength, durability, etc.). Finally, The Innovation Cell enables the group to take ownership of new techniques such as MuCell®, a process dedicated to cosmetic applicators.

The Innovation Cell plays a significant role in eco-design projects led by the group’s dedicated cell and centred on the 3 “Rs”.